The Green Tech Paradox: The Minerals We Need For A Cleaner Tomorrow

The goal of a sustainable and clean energy future is crystal clear.

However, the challenge we now face is that the green technologies and infrastructure we are championing demand minerals, and rare earth elements which have to be sourced through mining. There's no substitute.

It's a paradox – the urgent shift to green energy relies on the continued excavation of our planet.

Demand for minerals and rare earth elements is skyrocketing, and according to the International Energy Agency, by 2030, supply from existing mines and projects will barely keep pace with the expected surge in demand.

Despite Australia being the single largest producer of lithium based on our net zero targets, the current worldwide production volume of lithium and cobalt mines, essential for battery production, will only satisfy half of our requirements. Copper, a component in almost all electrical technologies, isn't far behind either.

Rare earth elements like neodymium and terbium, vital for the efficient functioning of wind turbines and electric vehicles, will be in greater demand than ever.

When mining for these critical minerals, it's also estimated that one hundred billion tonnes of waste is generated by the 3500+ active sites globally.

So, the pressing question becomes: How will future mining processes adapt as we dig deeper to power the clean energy revolution?

Here are three sustainable approaches that could change the way the industry operates:

A clear illustration of this can be drawn from Dr. Corder of the University of Queensland. Discussing the potential of mining byproducts, he mentions the reuse of cobalt, a byproduct of copper mining, by other sectors.

As Dr. Corder articulates, "The by-product and tailings could be ignored if cobalt is not core business, but with a different focus from the mining company and possibly in collaboration with a third party, the material could be reprocessed to extract cobalt and possibly other metals,"

Rather than being thought of as 'waste', valuable materials can be recovered and reused by other industries.

At the recent AIMEX mining conference, Valentina Petrone, Associate Director & Circular Economy Lead AUNZ from WSP, emphasised the importance of adopting circular economy principles throughout the mining project lifecycle.

Not limited to just using recycled materials during construction phases for example, the focus is on 'designing out' waste to begin with.

It requires a holistic approach working with different teams and stakeholders to educate and help set up best practices from design through to planning the rehabilitation of old mine sites.

#3. Creative Rehabilitation of Abandoned Mines: Worldwide, mine sites occupy 57,277 km² of land. Interestingly, over half of these mining sites are found within just five nations: Australia, China, the United States, Russia, and Chile.

Of those there are over 60,000 abandoned mines in Australia, with some dating back to the Gold Rush in the 1800's.

Enter Green Gravity, an Aussie clean energy startup based in Wollongong, New South Wales. Their groundbreaking approach? Repurposing old mine shafts to create renewable energy.

Green Gravity's unique energy storage system involves moving heavy weights up and down these shafts. As the weights rise and fall, they generate and store energy, a resourceful way to revive an old mine site.

And this is just one of a number of creative ways to rehabilitate and revive an old mine site.

From repurposing waste to designing a second life for old mine sites, these creative approaches are a reminder that these paradoxes whilst challenging, will bring about new ideas, collaboration, and strengthen our ability to adapt.

References:

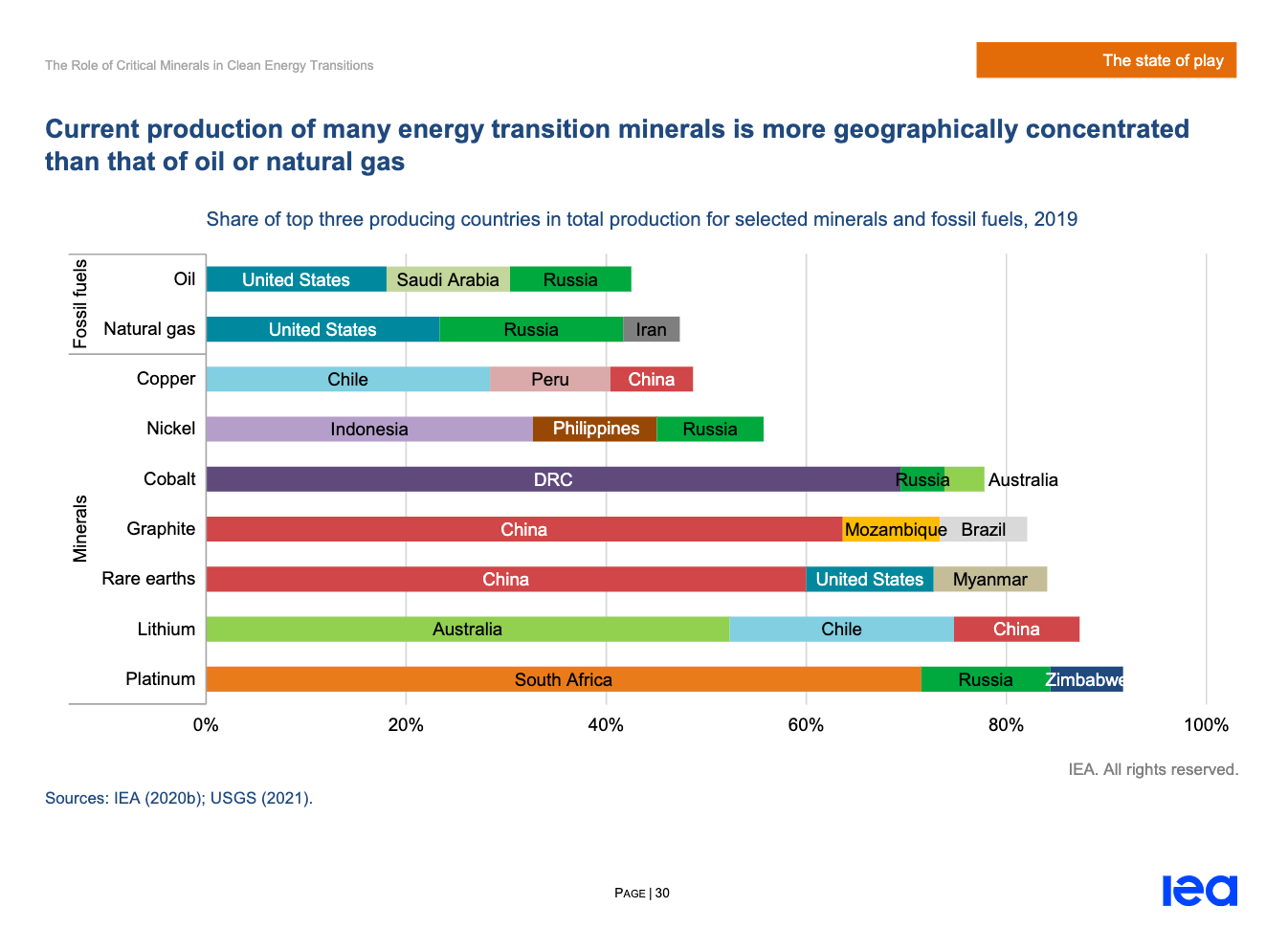

- International Energy Agency. (2021). The Role of Critical Minerals in Clean Energy Transitions.

- Connell, B. The circular economy: A sustainable future for mining. Sustainable Minerals Institute (SMI), University of Queensland.

- Rankin, W.J. (2015). Towards zero waste. AusIMM Bulletin, 2015, 32–37.

- Global mining land data - FINEPRINT. (2020). Brief No. 12.

- Green Gravity

- WSP Australia